Potassium Monopersulfate (KMPS): A Versatile Solution for Multiple Industries and Applications

- Solomon Matzner

- Sep 3, 2024

- 5 min read

Potassium Monopersulfate (KMPS) is a powerful oxidizing agent that has found its way into various industries due to its versatility and effectiveness. As businesses and organizations across the globe seek safer, more efficient, and more environmentally friendly solutions, KMPS stands out for its ability to meet diverse needs. In this article we explore the different industries and applications where KMPS is used and how it brings value to each sector.

1. Industrial Water Treatment

KMPS plays a crucial role in both municipal and industrial water treatment processes. It is widely used to oxidize organic and inorganic contaminants, such as phenols, sulfides, and metals like iron and manganese, improving water quality. KMPS helps reduce chemical oxygen demand (COD) and biological oxygen demand (BOD), ensuring that water is safe for public consumption and meets regulatory standards. In industrial wastewater treatment, KMPS breaks down complex organic pollutants and controls odors caused by sulfur compounds, while also eliminating pathogens, making treated water safer for disposal or reuse.

How KMPS is Used: KMPS is typically added to water systems in either powdered or liquid form. It reacts with contaminants, breaking them down into harmless substances, which enhances water quality and reduces environmental impact.

2. Environmental Applications

In the realm of environmental remediation, KMPS is a powerful tool for soil and groundwater cleanup. It is particularly effective in breaking down organic pollutants such as hydrocarbons and chlorinated solvents, which are common in contaminated sites. KMPS is also used to treat hazardous waste streams, neutralizing pollutants and converting them into less harmful substances, making the waste safer for disposal.

How KMPS is Used: In environmental applications, KMPS is applied directly to contaminated sites or added to waste streams. Its strong oxidizing action decomposes harmful organic compounds, supporting effective environmental cleanup and restoration efforts.

3. Pool and Spa Maintenance

KMPS is a popular choice for pool and spa maintenance as a non-chlorine oxidizer. It effectively eliminates organic contaminants like sweat, body oils, and cosmetics, helping to maintain water hygiene without the unpleasant odor and skin irritation often associated with chlorine. KMPS also improves water clarity, reducing the need for frequent water changes and additional sanitizing chemicals.

How KMPS is Used: In pools and spas, KMPS is added directly to the water as part of a regular maintenance regimen. It quickly reacts with and breaks down organic contaminants, ensuring clean, clear water and enhancing the overall swimming experience.

4. Pharmaceuticals

In the pharmaceutical industry, maintaining a sterile environment is paramount. KMPS is utilized for disinfecting equipment, surfaces, and facilities, effectively eliminating a wide range of pathogens, including bacteria, viruses, and fungi. This ensures a sterile production environment, which is critical for maintaining pharmaceutical quality. Additionally, KMPS is sometimes used to oxidize raw materials during the synthesis of certain pharmaceutical products, ensuring precise chemical reactions.

How KMPS is Used: KMPS is applied as a disinfectant solution for cleaning equipment and surfaces or added to chemical processes where controlled oxidation is required, helping to maintain a clean and contaminant-free environment.

5. Manufacturing

In manufacturing, KMPS serves multiple roles. It is used for surface treatment and cleaning, effectively removing organic contaminants, oils, and residues, ensuring surfaces are properly prepared for further processing, such as coating or painting. In the textile industry, KMPS is used as a bleaching agent that whitens and brightens fabrics without damaging fibers, providing a safer alternative to chlorine-based bleaches.

How KMPS is Used: In manufacturing processes, KMPS is applied in cleaning solutions for surface preparation or as part of a bleaching bath for textiles. Its oxidizing properties ensure clean, high-quality outputs in various manufacturing applications.

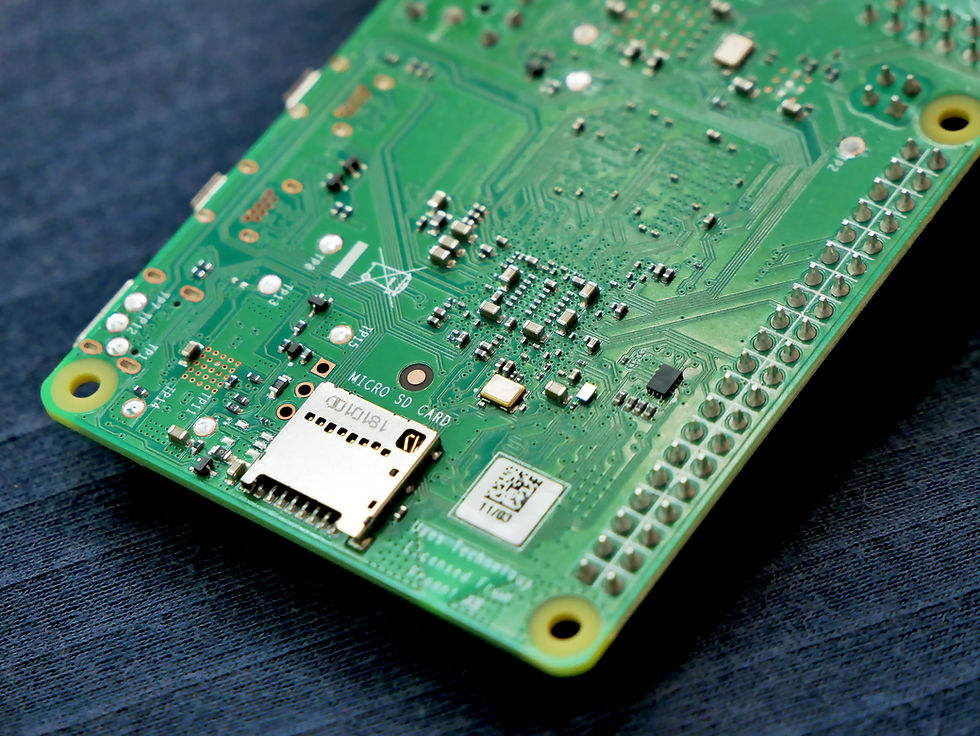

6. Electronics (PCB Surface Etching)

The electronics industry relies on KMPS for precise and controlled etching of printed circuit boards (PCBs). KMPS helps remove unwanted copper from PCB surfaces, creating fine conductive pathways essential for high-quality electronic circuitry. It is also used to clean electronic components by removing flux residues and other organic contaminants that can affect performance.

How KMPS is Used: KMPS is included in etching solutions to oxidize and remove specific materials from PCB surfaces. Its controlled action is vital for producing detailed electronic components with minimal defects.

7. Agriculture

In agriculture, KMPS has several important uses. It is employed to disinfect soil contaminated with organic pollutants or pathogens, promoting healthier crop growth and reducing the risk of plant diseases. In aquaculture, KMPS is used to maintain water quality in fish and shrimp farming operations by oxidizing organic matter and controlling waterborne pathogens. Furthermore, KMPS is a key ingredient in Viroxide products, which are used for disinfecting animal housing and equipment on cattle, swine, and poultry farms, effectively eliminating a wide range of pathogens and enhancing farm biosecurity.

How KMPS is Used: For soil disinfection, KMPS is applied to the soil as a treatment to reduce harmful microorganisms and organic pollutants. In aquaculture, KMPS is added to water systems to maintain cleanliness and prevent disease. On animal and dairy farms, KMPS-based disinfectants are sprayed or applied to housing, feeding areas, and equipment to ensure thorough disinfection and biosecurity.

8. Other Applications

Beyond the industries mentioned, KMPS is also used in several niche applications. In the cosmetics industry, it serves as a gentle oxidizing agent in exfoliating scrubs and facial masks, enhancing product performance without causing skin irritation. In various industrial settings, KMPS is a powerful oxidizer for cleaning surfaces and equipment, effectively breaking down organic contaminants. It is also used to control biofilm formation in industrial water systems, such as cooling towers and heat exchangers, improving operational efficiency and reducing maintenance costs.

How KMPS is Used: In cosmetics, KMPS is incorporated into formulations. In industrial applications, it is applied as a cleaning agent or directly to systems where oxidation is required to control contamination and biofilm buildup.

Conclusion

Potassium Monopersulfate (KMPS) is a versatile and effective oxidizing agent that meets the diverse needs of multiple industries. Whether it's treating water, maintaining pool hygiene, supporting pharmaceutical manufacturing, enhancing agricultural practices, or ensuring environmental remediation, KMPS provides a reliable solution that combines efficiency, safety, and environmental friendliness. By understanding its applications and benefits, businesses can leverage KMPS to achieve superior outcomes in their respective fields.

Interested in learning more about how KMPS can benefit your industry? Contact us today to discuss your needs or request a sample!

Learn more about our products or request Documentation

Contact us at info@bspsourcing.com

About Us:

BSP Sourcing is a trusted sourcing partner for chemicals and raw materials offering Strategic Sourcing and Supply Chain Solutions across industry segments. BSP Sourcing is part of BioAktive Group Inc, a US company supplying best in class ingredients, raw materials and solutions at the intersection of chemicals and life sciences. For more information, please email us info@bio-aktive.com or info@bspsourcing.com.

For more information, please contact:

Solomon Matzner

President

BioAktive Group Inc

For media inquiries or for more information please contact us at info@bio-aktive.com

Comments